I’m sure that if you’re new to saws, it’s hard to sort out the numerous types of electric saws properly. Moreover, each saw modification has its own characteristics: power, depth of cut, domestic or professional, corded or cordless, stationary or hand-held, etc. So, I want to help you figure out what device you need and what are the differences between them. In the article, I’ll define the main features of every power saw type and the purposes for which they are designed. You’ll find here a detailed description of all power saw types, so it will be much easier for you to dive into carpentry.

Distinguishing Electric Saw Types

Contents

There are a bunch of different kinds of electric saws presented on the market by many manufacturers. Here are the types of power saws:

- table saws;

- circular saws;

- miter saws;

- chop saws;

- radial arm saws;

- chainsaws;

- reciprocating saws;

- jigsaws;

- band saws;

- scroll saws;

- panel saws;

- rip saws;

- track saws;

- tile saws;

- flooring saws.

Table Saw

The table saw is a widely used tool among regular carpenters. Such a universal device at a reasonable price is usually installed in workshops on a stationary basis or transported straight to the job site. Multi-purpose and pretty accurate saws are in demand for amateurs as well as professionals. Moreover, a regular circular saw could be easily turned into a table saw after some manipulations.

What is it used for?

The table saw is a versatile instrument, so it provides a wide range of functions: from cutting small and tiny plywood pieces to cutting firewood or large dimensional lumber of any wood type. Also, tiles and soft metals can be processed by the device, but don’t forget that such features require special blades and a particular saw model in some cases.

The diversity of table saw modifications allows carpenters to use it for different purposes in different places.

Main purposes:

- Straight ripping and crosscutting of large wood pieces;

- Making bevel cuts;

- Cutting soft metals.

Attention: requires special blades!

Structure

Typically, it’s a corded stationary device. In simple terms, it’s just a spinning round blade protruding from a special table. Engine and other stuff are hidden in the metal or plastic box just under the table. However, there are additional features included; here is the list of the major ones:

Rip fence

Works as a guide and allows you to cut in the one parallel to the blade.

- Angle and height adjustment

A switch, typically installed in the lower part of the table, allows you to set a particular height and angle (usually, a 30-degree lean limit is set for both the left and right sides) of the blade.

- Blade guard and dust collector (optional)

A safety plastic cover and a special collecting hose were installed to prevent dust from scattering around the room.

You can make bevel cuts with a saw table and even miter cuts with the use of a miter gauge.

- Most common blade sizes: 8” – 10”.

- Max angle for bevel and miter cut: 40 – 45 degrees.

- The Max depth of cut and width of the cut depends on blade size.

Numerous modifications to the table saw exist:

- Compact table saw

Small, cheap, and lightweight solution.

- Jobsite table saw

Compact device with wheels.

Massive and expensive device for super-accurate cutting.

and etc.

Overall, the table saw is an accurate and affordable stationary solution for the regular carpenter with his own workshop that can be useful for cutting large pieces of dimensional lumber, plywood, or even metals.

Circular saws

One of the most popular electric wood saw types is widely spread all over the world due to its compactness, easy usage, high capability, and low price. Even regular people not interested in carpentry choose this device as a part of a home toolbox. Also, such a handy and relatively powerful device is a value among amateur carpenters. However, professionals prefer buying other, more expensive, and massive solutions to achieve maximum possible accuracy and efficiency.

What is it used for and what are its advantages?

Overall, the circular saw main features are similar to the table saw ones, but it has a bunch of notable benefits.

Firstly, the small sizes and prevalence of cordless models make circular saws much more convenient to work with on non-permanent job sites on an ongoing basis. For the same reasons, every family can afford to keep the instrument at home.

Secondly, you operate the saw but not the material. That is some kind of fundamental difference between a table saw and a circular saw, which might be a significant advantage for some carpenters.

Thirdly, due to the absence of a built-in table and other additional stuff, the price is pleasing to the eye. Obviously, expensive, high-accurate and durable models for professionals are presented on the market too.

A circular saw is a universal device, so it can be used for cutting nearly anything.

Main purposes:

- Fast and convenient in cutting plywood, dimensional lumber, plinths, and parquet;

- Cutting large plywood pieces;

- Making bevel cuts;

- Cutting logs into firewood;

- And others.

Structure

“It is a table saw but reversed and without a table”

An unknown carpenter

Take a spinning blade connected to the handle of the engine, and you’ll get a circular saw. Genuinely, circular saws are very familiar with table saws. Half of the parts are the same; here is the list:

- circular blade;

- engine;

- blade guard;

- cut adjustment switches;

- handle;

- saw shoe;

- cord or Li-ion batteries etc.

Moreover, it’s possible to convert a circular saw into a primitive table saw.

- Max angle for bevel cut: 45-50 degrees.

- Most common blade sizes: 6” – 8”.

- Max depth of cut and width of the cut depends on blade size.

Special circular saws designed for metal or concrete cutting are presented on the market. However, circular saws don’t have many far different variations except table saws and miter saws which are considered to be entirely separate saw types. Only a couple of these should be mentioned:

- Mini circular saws

Compact solutions with extremely small blades.

- Sidewinder circular saws

The engine is placed on one side of the device to provide high blade speed (up to 5000 – 6000 RPM) for a smaller size.

- and others.

In my opinion, a circular saw provides the best efficiency-price balance for customers. Easy and comfortable usage is a result of relatively simple construction, which, however, includes some vital features like the ability to make bevel cuts. A circular saw is a good choice for an amateur carpenter working with large volumes of material on different job sites.

Miter saws

A miter saw is so well-designed that it gained a lot of recognition and got many variations. As a result, it became a separate saw type while being only a branch of the circular saws family in the past. The machine allows carpenters to make larger and more accurate cuts than a circular saw. It’s a very versatile instrument, too, so amateurs and even professionals frequently buy it for their workshops at a reasonable price.

What is it used for and what are the benefits?

In general, ways of usage don’t really distinguish from a table saw or circular saw. However, larger and harder wood kerfs can be cut even more accurately on this saw, and bevel and miter cuts are the highlights of this saw type. Even more, working with a miter saw requires less physical effort because of structure specificity, which means that cutting metals is much easier with this device.

Main purposes:

- Making accurate angled cuts;

- Crosscutting large wood pieces;

- Easy and accurate cutting of smaller material pieces;

- Cutting soft metals etc.

Structure

A miter saw is a swing arm with a blade mounted on its tip. You place the wood on the platform under the blade and lower the arm making a cut.

Miter saw consists of these parts:

- Engine;

- Shaft and circular blade;

- Handle and saw head;

- Base;

- Angle adjustment switches etc.

A distinctive feature of miter saws is angled cuts. The blade can be pivoted on one or both sides, allowing you to make miter cuts, which, in conjunction with the ability to do bevel cuts, makes it so demanded among carpenters.

It has a wide range of modifications:

- Sliding miter saw

Allows longer wood pieces thanks to the slider.

- Compound miter saw

2-in-1 device – In a closed position can be used as a table saw.

- Dual miter saw

Unlike the standard miter saw, the dual miter saw is capable of making bevel cuts on both left and right sides.

- and others.

- Max angle for bevel and miter cut: 45-55 degrees.

- The Max depth of cut and width of the cut depends on blade size and the presence of a slider, which can increase the width of the cut several times without losing accuracy.

- Most common blade sizes: 8” – 12”.

Overall, a miter saw is a good stationery (but can be brought onto the job site as well) solution for amateurs and professionals that provides maximum efficiency and accuracy in cutting large pieces of material with minimum effort at an affordable price. A variety of miter saw modifications allows one to choose the best option for particular tasks. From my experience, that is the best middle-sized instrument for working with large volumes of material on an ongoing basis.

Chop saws

The “smaller brother” of a miter saw is frequently considered only a miter saw type. However, there are enough distinctive features to include in our overview as a separate saw type.

What is it used for?

In contrast to miter saws, chop saws are specially designed for working with metals. It doesn’t mean you can’t use it for cutting wood or tiles, but in this way, the functionality will be limited.

The main purpose of the saw is to make accurate cuts in thick metal pieces. So, typically it’s bought by specialists for the needs of one particular task. Fortunately, due to the low price, most carpenters can afford to buy it just in case.

Don’t forget that cutting metals requires special blades.

Structure

The principle of a chop saw anatomy is very similar to miter saws – an arm installed on the platform with a blade mounted on it. Also, you could see in the photos, a mechanism installed right on the saw base. This is a clamp that fixes the part of the material in one position. Such a clamp is required for this saw type because of a high pressure appearing while cutting metal. Nevertheless, a chop saw is incapable of doing angled cuts.

- Engine;

- Circular blade;

- Handle;

- Massive metal blade guard;

- Clamp for the material;

- Base, etc.

A much bigger common blade diameter of a chop saw is needed for cutting metal. Most popular blade sizes for chop saws: are 12” – 15”.

The Max depth of cut and width of the cut depends on blade size.

The chop saw doesn’t have “compound” or “slide” modifications as a miter saw has because of its narrow specialization.

Low prices and high efficiency in cutting tight metal parts make a chop saw the best solution in its category.

Radial arm saws

The main feature of the most unusual and uncommon saw type is making perfect crosscuts of tiny wood pieces. Unfortunately, radial arm saws are being replaced by cheaper and more universal analogs, like table saws or miter saws, and there is only one company left in the USA that still manufactures this saw type. But back in the day, pretty much every self-respectful professional used to have it in his own workshop.

However, these machines are demanded by some carpenters because of several essential advantages.

Why is it still used and for which purposes?

The main advantage of radial arm saws is their versatility. Thanks to the slider that can be rotated itself and the presence of an angled cutting feature, radial arm saws are capable of completing a wide range of tasks with minimum effort. Thanks to the extremely large slider, the saw is capable of making large and super accurate crosscuts, so it’s perfectly suitable for ripping long pieces of stock. This saw type is typically used for:

- Ripping large and tiny pieces like boards, plywood, or rabbet;

- Cutting not large dimensional lumber;

- Making bevel and miter cuts;

- and other work.

As you can see, almost all of these tasks can also be completed with a miter saw or with other types of electrical saws, but high price, expensive maintenance, and inability to cut wide dimensional lumber became a decisive factors in the fall of radial arm saws popularity.

Structure

A radial arm saw was installed on the base (a metal table). A slider is mounted parallel to the table on top of some kind of thick pillar protruding from the table. A slider is divided into two parts – the first one is hardly joined to the pillar and the second one can be rotated. The second part is the slider itself, which provides the track for a saw head moves like on track.

You place the material on the table and move the saw head to make a cut.

The saw is typically manufactured with an in-build table which makes radial arm saw sizes pretty massive.

- Base

In-build table with a backbone for the slider.

- Slider

A track is installed on a support pillar and hanging off in the air.

- Saw head

A part of the saw with handle, blade, and engine mounted directly on the slider.

- and others.

- The height of the blade and cut angles are adjustable.

- Max angle for bevel and miter cuts – 45 degrees.

- Typical blade sizes: 10”-12”.

I consider a radial arm saw an even better and more versatile stationary device than a table or miter saw in some cases.

However, large sizes, relatively high prices, and low depth of cut make me wonder if it’s necessary to buy this saw type if you only don’t work with large and tiny pieces on a daily basis.

Chainsaws

Now we are moving to a completely different saw type which distinguishes us from previous saw types on a fundamental level. A chainsaw is a portable and relatively lightweight device that is used for cutting down trees. These hand-power saw types are very popular among woodsmen and people who prefer to live in the country.

What is it used for?

Due to the extremely large length of the cut, chopping down trees is the main call of all chainsaws. If you want to use it for some other kind of task, you should bear in mind that the cut made by the chainsaw is rough and uneven, so it’s unsuitable for delicate work.

Purposes

- Chopping down trees;

- Cutting off branches;

- Cutting fallen tree trunks into smaller pieces;

- Cutting logs into firewood etc.

Structure

Long-chain with metal teeth spinning on a steel bar attached to the engine with a handle. Main chainsaw parts:

- Guide steel bar and bar nose;

- Chain with sharp teeth;

- Electric engine;

- Handles;

- Cord or batteries etc.

There are two main chainsaw types – gasoline and electric. Typically, gas saws are more powerful and durable, but the advantages of electric saws are silent work, lightweight, and ease of use.

Ultra-portable models with Li-on battery supply are also on-demand among carpenters.

- The most common bar length: is 16”-24”.

- The length of the cut is typically 2” shorter than the bar length.

Also, do not forget about safety measures – chainsaws are far more dangerous than saws with circular blades. An electric chainsaw is a perfect device for working with trees, bushes and logs. Portability and affordable price make it so popular among saw buyers.

Reciprocating saws

Among all these different kinds of power saws, this is the most unusual saw type for a newbie. In fact, it is a portable electric ripping saw. The main work concept is the same as for rip saw – a blade moves forward and backward, making a cut. Because of its wide range of uses, it’s quite a popular tool among carpenters that work on house remodeling.

Where is it used and some disadvantages?

As mentioned earlier, this is a perfect instrument for house remodeling and repair. Unlike a circular saw, due to the long and tiny blade, the reciprocating saw allows you easily get to hard-to-reach places like railings, siding, casing, or door jambs. Moreover, it’s capable of cutting steel or plastic pipes.

- Purposes:

- Cutting everything that is hard to access with a circular saw – roof beams, jambs, railing and etc.;

- Cutting pipes;

- Making plunge cuts, etc.

Working with these types of sawing machines is not an easy task. You have to keep a hard vibrating saw in one position and push it to make a deeper cut. Unfortunately, reciprocating saws do not provide excellent cut clearance and fast cutting.

Structure

A Reciprocating saw is a long blade protruding from the saw head. The blade moves backward and forward, making a cut. Visually this saw type is slightly longer than other saw types.

Main parts:

- Long and tiny blade;

- Saw head with engine and handle etc.

- Most common blade length: is 6”-9”.

- The length of the cut is typically 1”-2” shorter than the blade size.

The Reciprocating saw is unsuitable for a workshop, but it’s a very useful and handy device for remodeling. Carpenters making money from house repairs value this device for its portability, small size, and good price-quality balance.

Jigsaw

Electric jigsaw has a bunch of similarities with a reciprocating saw, but the main purposes are different. Handy portable devices with some distinctive features are usually chosen for making curved cuts.

What is it used for?

Curved accurate cuts are the strongest point of a jigsaw. Other saws are designed only for making straight cuts but not a jigsaw. Moreover, sometimes reciprocating saws can be replaced by this saw – familiar functionality made it possible. Thanks to a tiny and long blade and a compact size, a jigsaw can cut in places where a circular saw is useless, but the necessity to put it on a plain surface for safe and accurate cutting significantly limits its possibilities.

- Main purposes:

- Making curved cuts;

- Cutting not thick metal parts;

- Making plunge and bevel cuts, etc.

Structure

In simple terms, it works just like a manual jigsaw but uses different blade types. A long and tiny blade protrudes vertically from the plastic box with the engine and handle. A saw shoe is installed, so the saw can’t be set in a random position.

Thanks to the shoe, working with an electric jigsaw requires less effort than with a reciprocating saw. Additionally, cuts are clearer.

Jigsaw types:

- Pneumatic

A powerful device for professionals.

- Compound

Jigsaw and reciprocating saw in one device.

- Cordless or corded

Two blade types are used: U-shaped and T-shaped. You can read more about jigsaw blades here.

Most jigsaws are incapable of cutting through very thick wood – the most common blade size is just 4”, and the depth of cut is usually 1” shorter than the blade size.

A jigsaw is an irreplaceable portable instrument for making accurate curved cuts. So, if you don’t want to spend time cutting out some intricate shapes manually, that is a must have for you.

Band saws

A band saw is very similar to a jigsaw. However, this is a stationary machine targeted at completing more complex tasks. A band saw is the choice of a professional woodworker who really needs this machine.

What is it used for?

As well as jigsaws, band saws are capable of making curved cuts, even in thick planks. Also, this versatile machine is widely used for ripping wood and dimensional lumber into planks – it cuts with extremely high accuracy. Moreover, nearly everything can be cut on a band saw, including metal, tiles, plastic, pipes, etc. – that is the most versatile stationary machine.

Purposes:

- Making curved cuts in large wood pieces (3”-4” and wider);

- Ripping wood into planks;

- Ripping and cutting metal, plastic, etc.

Structure

A tiny blade is installed vertically between two big saw parts. It moves up and down, making a cut.

The majority of manufacturers present only stationary solutions, but some portable models are also available.

The most common blade length – is 14”.

Novices shouldn’t buy this machine because of the high price and large sizes. There are a lot more accessible options available among jigsaws or circular saws. Professionals frequently buy a band saw as a versatile machine for the workshop.

Scroll saws

A device very similar to a band saw. It’s lighter and cheaper, but still an overall good stationary device for making deep curved cuts.

What is a scroll saw best for?

In contrast to a band saw, a very tiny blade allows a scroll saw to make tight turns while cutting and, consequently, cut out more complex patterns. However, scroll saws are less powerful and have tiny blades. This is an advantage and a disadvantage at the same time: less power allows one to make more accurate cuts, but limits the ability to cut large wood pieces.

Purposes:

- Making accurate curved cuts;

- Ripping wood pieces, etc.

Structure

Just like a band saw, but smaller and wider. A tiny blade is installed vertically between two major saw parts.

A scroll saw has a significant throat diameter. It means that you can work with thin but large materials on this machine. Also, adjustment pedals and switches are included.

Scroll saws are sharpened for making super implicate curved cuts with more accuracy. So, if your purposes are familiar, this relatively compact device is your choice. However, I still don’t recommend buying it for beginners.

Panel saws

A narrow-specialized stationary tool designed only for one purpose – cutting large-sized wood pieces on rectangles.

Purposes:

- Cutting large plywood sheets;

- Cutting foam, acrylic, etc.

Structure

Technically, it’s a circular saw installed on a special frame. A sheet of material is placed on this frame and cut by a moving circular saw. Obviously, this is a solid structure that may be successfully maintained for many years.

There are horizontal and vertical types of saws. Even more, several blades are frequently installed on horizontal-oriented models to provide higher efficiency.

As you can see, panel saws are good solutions for companies or for some professionals, but not for regular woodworkers.

Rip saws

A power rip saw is called a reciprocating saw, so check the paragraph about it.

Track saws

The solution collected all advantages of a table saw and circular saw. Track saws are the best for cutting large material pieces.

Main purposes:

- Cutting large pieces of plywood;

- Cutting foam, etc.

Structure

In people’s terms, a track saw is a circular saw with long guides. Saw head moves in a special track, making super accurate and long cuts.

The track saw provides a good balance between portability, price, and accuracy, so if you are working with large sheets of material and your budget is limited, this is your choice.

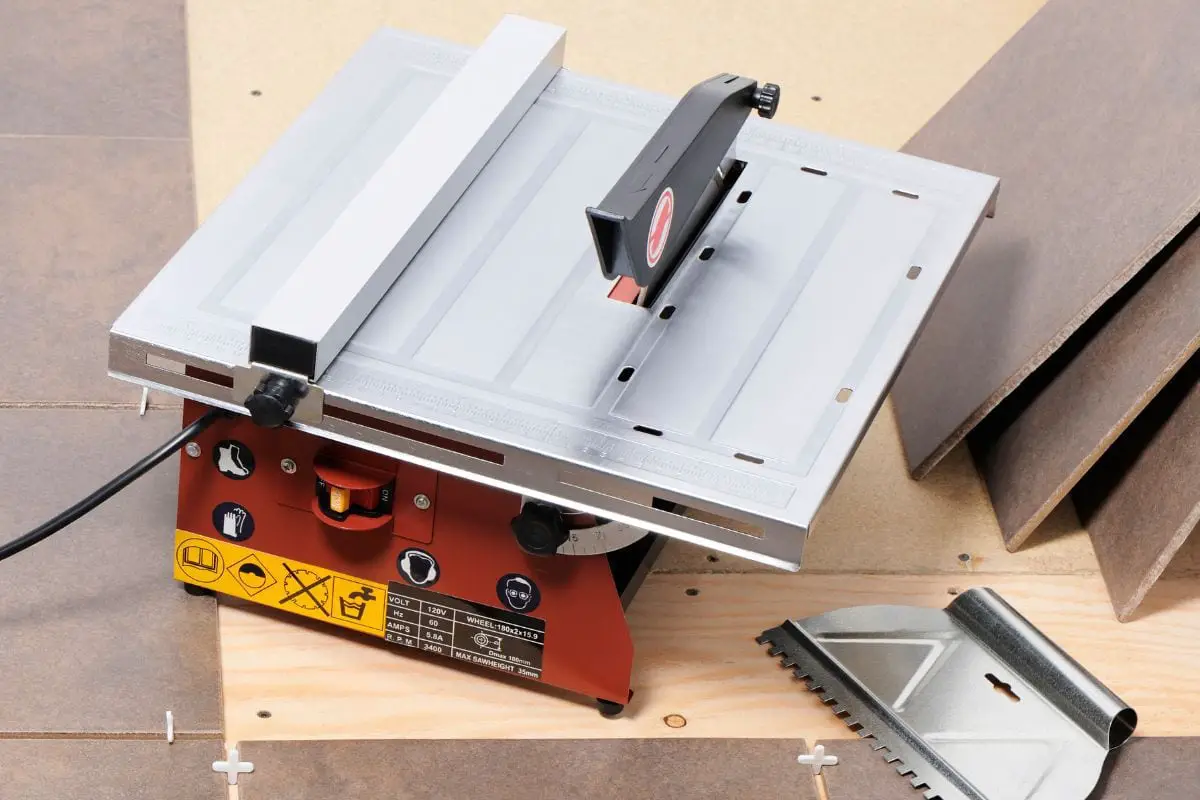

Tile saws

A narrow-specialized device similar to a table saw. Tile saws are not that popular, but some carpenters value this tool for its low price, good portability, and good characteristics in cutting tiles and ceramics.

Purposes:

- Cutting tiles.

As you can see from the name, tile saws are used only for cutting tiles. Surely you can use it for cutting wood or some other materials, but sometimes it may be dangerous, so I don’t recommend doing that.

Structure

There are a bunch of different tiles saw types with structures very similar to table saws, miter saws, circular saws, and even radial arm saws. A distinctive feature of almost all tile saws is the presence of water cooling. In other words, a place of cut is constantly watered to prevent heating from cutting. Saws with this system are called wet saws, but, however, there are special dry tile saws that do not require a water supply. Some of the major tiles saw types:

- A handheld wet tile saw – similar to a circular saw.

- Dry tile saw. Tile saw without water cooling.

- Table tile saw with rolling tray. Complex design for cutting extremely large tiles.

- Bridge tile saw – a sliding saw with a bridge-shaped track provides good cutting length.

A tile saw is a low-budget device for working with tiles in large volumes. It cuts much faster and more accurately than manual tools, so if you work with tiles frequently, you may take one of the tile saw models.

Flooring saws

A hand tool with a long track designed especially for cutting flooring.

A useful portable device in house finishing allows you to cut laminate, hardwood, LVT, etc. fastly and accurately. Also, flooring saws are capable of cutting tight sheets of wood.

Purposes:

- Cutting flooring: laminate, hardwood, LVT, vinyl, parquet, etc.

Structure

Sliding mechanism with the saw installed on a large platform. You move a saw head making a straight cut. Also, it can be used as a table saw. However, blade size (typically 4”-5”) doesn’t allow you to work with large wood pieces.

A flooring saw is a good choice for carpenters that frequently face the problem of making even flooring.

FAQ

The list of the most common questions about electric saws.

Which power saw is most versatile?

A Circular saw is the most universal instrument. With a circular saw, you can cut large wood pieces, dimensional lumber, plywood, metals, plastic, pipes, beams, plinths, and more. Portability is also a strong side of a circular saw. Even more, it’s possible to turn a circular saw into a table saw.

Can I use a jigsaw instead of a circular saw?

Sometimes yes. Bear in mind that a jigsaw’s depth of cut is usually shorter than a circular saw’s, so a jigsaw is not suitable for cutting large pieces. Moreover, jigsaws are less powerful, so you’ll spend far more time making a cut than with a circular saw.

Can a miter saw cut horizontally?

No, it can’t. Maximum cutting angle of miter saw – 45-50 degrees. If you want to cut horizontally, just try to rotate your piece of material if it’s possible. Different power saws are presented on the market, but few of them are cut horizontally.

What is the difference between a miter and a bevel?

A miter cut is a cut made with a blade set vertically at any angle except 90°. In contrast, while making a bevel cut a disk has to be tilted at any angle except 90° in relation to the surface. Also, a fully straight cut is called straightforward.

What Power Saw Should I Choose?

As always, everything depends on your purposes. Do you need a versatile, handy, and not expensive tool? Take a circular saw. Do you face the problem of making curved cuts? A jigsaw will help. Always having trouble with cutting tiles? A tile saw is your choice.

I hope you’ll find the best solution personally for you. If you already have a saw, write in the comments below about it. Which saw type did you choose? For which tasks do you use it? Share your experience.