Everyone knows that today it is quite difficult to do without a backup power source because it can provide electricity to any area or home. Each such device runs on gasoline or diesel, but in addition to that, the unit requires high-quality oil for proper operation.

Modern stations are equipped with a low oil pressure shutdown system that protects the installation from low oil levels in the tank. If the oil pressure drops below a certain level, the low oil pressure cutoff switch will trip and the engine will shut down. It will simply stop starting, so if you can not start the construction, you should first measure the oil level or look at the display.

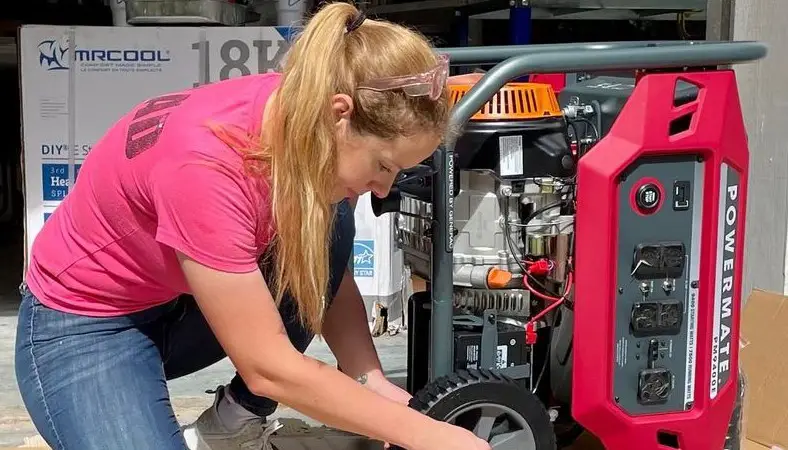

Review Sensor on Generator

Contents

What is the oil sensor in the generator? In fact, it is an ordinary float switch, which regulates the liquid level and if it falls below the permissible norm, it instantly sends a signal to the panel. The latter stops the motor of the unit and short-circuits the high-voltage voltage of the ignition elements on the frame of the unit.

What Is the Oil Sensor in the Alternator For?

The oil sensor in the alternator is for monitoring the oil level in the engine. It prevents the generator from running when the oil level is low, thereby extending its service life.

Precautions

- Oil filling work should be done outdoors;

- You must wear safety glasses, a respirator, and insulated gloves;

- Serious breakdowns can only be corrected by a specialist, so it is better to contact special organizations that deal with the repair of power plants;

- Keep in mind that the generator gets hot during operation and you should be careful when touching it.

How Oil Sensor Works

An oil sensor is a device that is used to measure the level of oil in an engine. The sensor is usually located in the oil pan, and it consists of a float that is connected to a rod. The rod is connected to a switch that is mounted on the oil pan.

When the engine is running, the oil level in the pan will rise and fall as the oil is used. The float will rise and fall with the oil level, and the switch will be activated or deactivated depending on the position of the float.

Tools and Materials

You will need:

- Wrench set;

- Socket set;

- Few screwdrivers.

Pros and Cons Bypass Low Oil Sensor on Generator

Pros:

- Bypassing the low oil sensor will allow the generator to continue to run even if the oil level is low. This can be useful in a situation where the generator needs to run for a long time and it is not possible to stop and check the oil level;

- Bypassing the low oil sensor can also be useful if the oil level is low but there is no oil leak. In this case, the generator can be run until the oil level drops below the level where the sensor would trigger, and then the oil can be added.

Cons:

- Bypassing the low oil sensor can be dangerous as it can lead to the generator running without enough oil. This can damage the engine and lead to a costly repair;

- Bypassing the low oil sensor can also void the warranty on the generator.

How to Bypass Low Oil Sensor

Before we begin, I want to remind you that bypassing the alternator sensor is only worth doing if you are sure the oil level is normal and the shutdowns are faulty.

If your generator is telling you that the oil is low, there is a way to bypass the sensor and continue using the generator. Here’s how:

- Locate the oil sensor. It is usually found near the oil fill cap or dipstick.

- Disconnect the sensor wire from the generator.

- Tape over the sensor wire so that it is insulated.

- Reconnect the wire to the generator.

- Start the generator and let it run for a few minutes.

- Check the oil level and add oil if necessary.

- Stop the generator and disconnect the wire again.

- Remove the tape and reconnect the sensor wire.

If after all the manipulations the generator still does not start, go to the service center, where the masters will be able to find out the cause of the failure and fix it.

Recommendations

Before disconnecting the sensor, you must check the oil level, and also check if the oil corresponds to the stated in the manual.

Frequently Asked Questions

Answers to questions that most often interest generator owners

Will a generator start with low oil?

If the oil level is too low, the engine will not start. This is done to protect the engine from wear and tear and extend its service life.

How do you check an oil sensor?

To check a generator’s low oil sensor, you will need to consult your generator`s owner’s manual. Each generator is different, so the manual will tell you the specific location of the oil sensor and how to test it.

Can you disconnect the oil pressure sensor?

Yes, you can disconnect the oil pressure sensor. But it would be a violation of operating rules and loss of warranty

Conclusion

A sensor is a float with a wire connected that opens the ignition circuit when the float moves too far from the set position. What is it for? This sensor is a kind of engine protection against oil starvation.

But there are situations when the oil level is normal and the sensor fails and does not allow the alternator to work. There are also situations when you need electricity urgently and then you decide at your own risk to disable the sensor.