An electric generator is a machine that converts mechanical energy into electrical energy. The reverse of this is an electric motor, which converts electrical energy into mechanical energy.

In an electric generator, a rotating shaft is used to spin a magnet around a coil of wire. The spinning motion causes the magnet to generate a magnetic field.

This field then interacts with the electric field of the coil to produce an electric current. The current is then sent to an external circuit where it can be used to power electric devices.

The strength of the current produced by the generator depends on the number of coils of wire in the machine, the speed at which the shaft is rotated, and the strength of the magnet.

Overview of Types and Kinds of Power Generators

Contents

An electrical generator is a device that converts non-electrical types of energy (mechanical, chemical, thermal) into electrical energy.

The function of any electrical generator is to produce an electric current. But in fact, the generator does not produce anything, but only converts one type of energy into another (as is characteristic of all energy processes in nature).

Most often, when saying the phrase “electric generator”, they mean a machine that converts mechanical energy into electrical energy. Mechanical energy can be obtained from gas or steam expanding under pressure, from falling water, or even by hand.

In either case, in order to obtain electrical energy from a generator, it must first transfer that energy in an acceptable form, most often mechanical energy.

For What Purposes Do We Need the Electric Generator to Work?

The electric generator can be used as a backup power supply source for various household and industrial consumers in cases of power outages, as well as to provide continuous power supply for country and cottage houses, exhibition and trade pavilions, remote from the main power grid settlements, summer camps, workers’ settlements, etc.

Professional power generators are used as a source of constant power supply for hospitals, administrative, and office buildings. This type is widely used in the construction industry, during an emergency, and during road-building works.

The advantages of professional units are the high motor source, economical fuel consumption, and high reliability under extreme conditions. The disadvantages are a considerable weight and the high noise level at work.

Industrial electricity generators of high capacity (over 100 kW) are used for the power supply of large manufacturing enterprises of different industries, factories, and industrial plants. It is characterized by high reliability, large dimensions, and complexity of maintenance.

How Electric Generator Works?

The principle of generating electrical energy in a generator is based on the phenomenon of electromagnetic induction, which consists of the fact that changes in space magnetic flux induce an electric field around this space.

And if a conductor is placed in the area where this induced electric field is present, then an EMF (electromotive force) will be induced in it, and the corresponding voltage can be observed (measured, used to power the load) between the ends of the conductor.

Variable magnetic flux is obtained in the generator by means of moving together with the rotor magnets or pole tips, magnetized by special windings – magnetization windings. Magnetizing windings are usually powered through brushes and contact rings.

Advantages and Disadvantages of Electric Generator

Like any device, electric generators have their pros and cons.

Here are the main ones:

Advantages:

- They are a versatile source of power;

- They can be used to power; homes, businesses, and even vehicles;

- Modern generators have high efficiency;

- Electric generators are relatively easy to operate and maintain;

- They can be used in many different applications, including backup power and off-grid power.

Disadvantages:

- Electric generators can be expensive to purchase;

- Electric generators can be noisy;

- Electric generators can produce harmful emissions;

- Electric generators need maintenance.

Classification of Electric Generators by Type

Electric generators are classified according to the following important technical and operational parameters:

- type of application;

- type of fuel used;

- number of phases;

- power.

Depending on the scope of application, a distinction is made between household, professional and industrial generators. Household gen sets are compact power units with a capacity from 0.7 to 25 kW, equipped with a gasoline or diesel combustion engine, with an air cooling system.

It is mainly used for standalone (backup) power supply of low-power household appliances, country and cottage houses, locksmith workshops, and various electric tools at construction sites. It is characterized by ease of operation and maintenance, low weight, low vibration, and noise level.

A professional electric generator is used as a source of constant power supply for hospitals, administrative, and office buildings. The advantages of professional units are their high service life, economical fuel consumption, and high reliability under extreme conditions. The disadvantages are considerable weight and high noise level during operation.

Industrial generators of high capacity (over 100 kW) are used for the power supply of large manufacturing enterprises of different industries, factories, and industrial plants. It is characterized by high reliability, large dimensions, and complexity of maintenance.

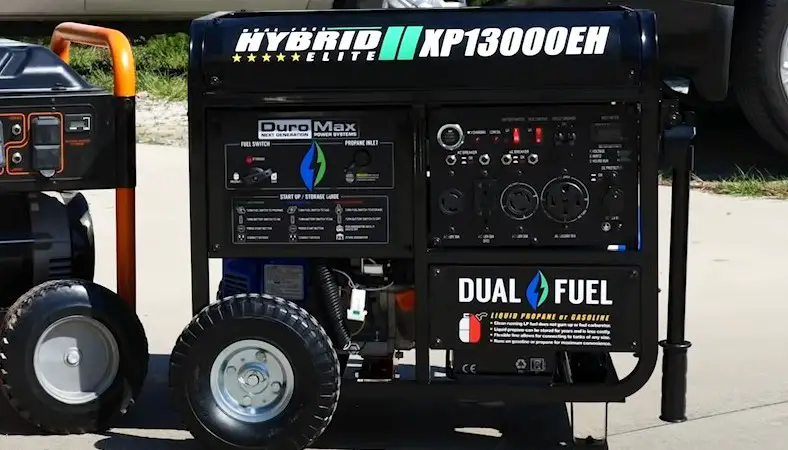

Depending on the type of fuel used, there are the following types of magnetic electric generators:

- gasoline;

- diesel;

- gas.

The gasoline generator produces electricity using the mechanical energy of the internal combustion gasoline engine shaft rotation. It is characterized by a limited power range (from 0.7 to 18 kW), mobility, relatively low weight, and ease of use.

It is mainly used as a backup power source for small summer houses, and summer camps. By virtue of the low motor source (500 motor hours) and the high cost of the generated electricity is practically not used for permanent power supply.

The diesel power generator is characterized by a wide range of power, and a high motor source (over 5000 motor hours). These versatile power units are used for standby power supply of settlements, hospitals, schools, and various industrial and construction equipment.

Due to the considerable weight (from 450 kg and more) and a high noise level at work, they are installed on the reinforced foundation, in separate noise-insulated premises. The sphere of application of gas-fired electric generators is industrial enterprises of different branches, private households, exhibitions,s and trade pavilions.

Power plants of this type are characterized by ease of operation and maintenance, high environmental friendliness, and low cost of fuel consumed, and electricity produced.

Depending on the number of phases, electric generators are divided into single-phase and three-phase.

Single-phase 110 V generators are used for the power supply of devices with 1-phase power supply, in power grids with 1-phase wiring.

Three-phase 110 and 380 V generators are used for the power supply of houses with 3-phase network distribution, 1- and 3-phase appliances, evenly distributing the power between each of the phases.

The power of electric generators is measured both in kilovolt-amperes (kVA) and kilowatts (kW). A distinction is made between rated power and maximum power. At the rated power the Genset operates for the main time, at the limit – only a few seconds.

The power of a particular model of generating set depends on its purpose, and the type of fuel consumed. Thus the power range of gasoline generators is from 0.5 to 18 kW; diesel generators – from 20 to 450 kW and more; gas-fired generators – from 20-25 to 400 kW and more.

Recommendations

When choosing a generator for your needs, one must take into account the total capacity of all power consumers connected to the generator (including those with high starting currents).

This is because many household and professional appliances consume much more power when switched on than during normal operation. Therefore, in order to ensure the reliable and safe operation of all appliances, as well as the generator itself, a power reserve of 20-30% should be provided.

Do not neglect the maintenance of your generator. Things like technical inspections, polarizations, and repairs should always be done in a regulated manner so that a sudden generator failure does not come as an unpleasant surprise to you.

Electric Generator Frequently Asked Questions

Frequently Asked Questions and Answers

How do portable generators work?

A portable generator is a small, self-contained unit that produces electricity. The working principle is the same as that of the larger models Most portable generators run on gasoline, propane, or diesel.

What size generator will power a house?

There is no definitive answer to this question as the size of the generator needed to power a house will depend on a number of factors, including the size of the house, the number of appliances and devices that need to be powered, and the wattage rating of the generator. The average home should have enough 7,500 watts.

What’s the difference between an inverter generator and a regular generator?

The difference manifests itself inside generators. Autonomy in operation, the ability to generate high-quality electricity, and protection against power surges – are the key features that distinguish the inverter models from conventional gasoline models. Inverter generators are more expensive than regular generators, but they are much quieter and more fuel-efficient.

How is electricity created in the generator?

The generator uses a coil of wire that is spun inside a magnetic field. This creates an electric current in the coil of wire.

Conclusion

A generator is a machine that converts mechanical energy into electrical energy. Generators are used in a variety of applications, from providing power for small handheld devices to large power plants.

Generators work by using a fuel source, such as gasoline, diesel, natural gas, or water, to turn a turbine. The turbine spins a magnet inside a coil of wire, which produces an electric current. The current is then sent to a transformer, which increases the voltage and sends it to an electric grid.

We hope that after reading this article you have learned how a generator generates electricity and you are left with no questions.